Precision Cold-Rolling of Stainless Steel Strip: From Raw Material to Soft-Tempered Finish

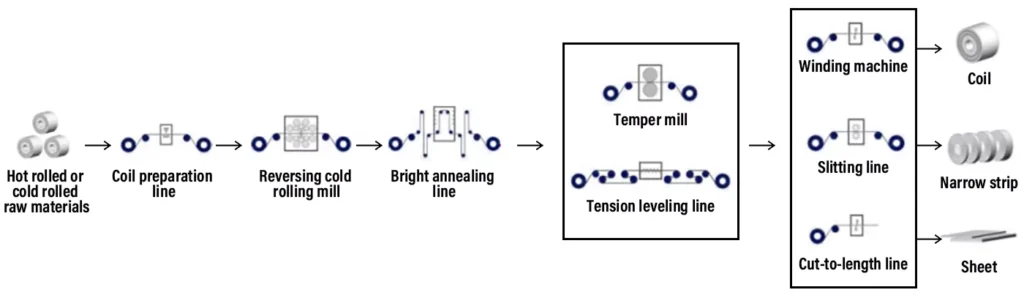

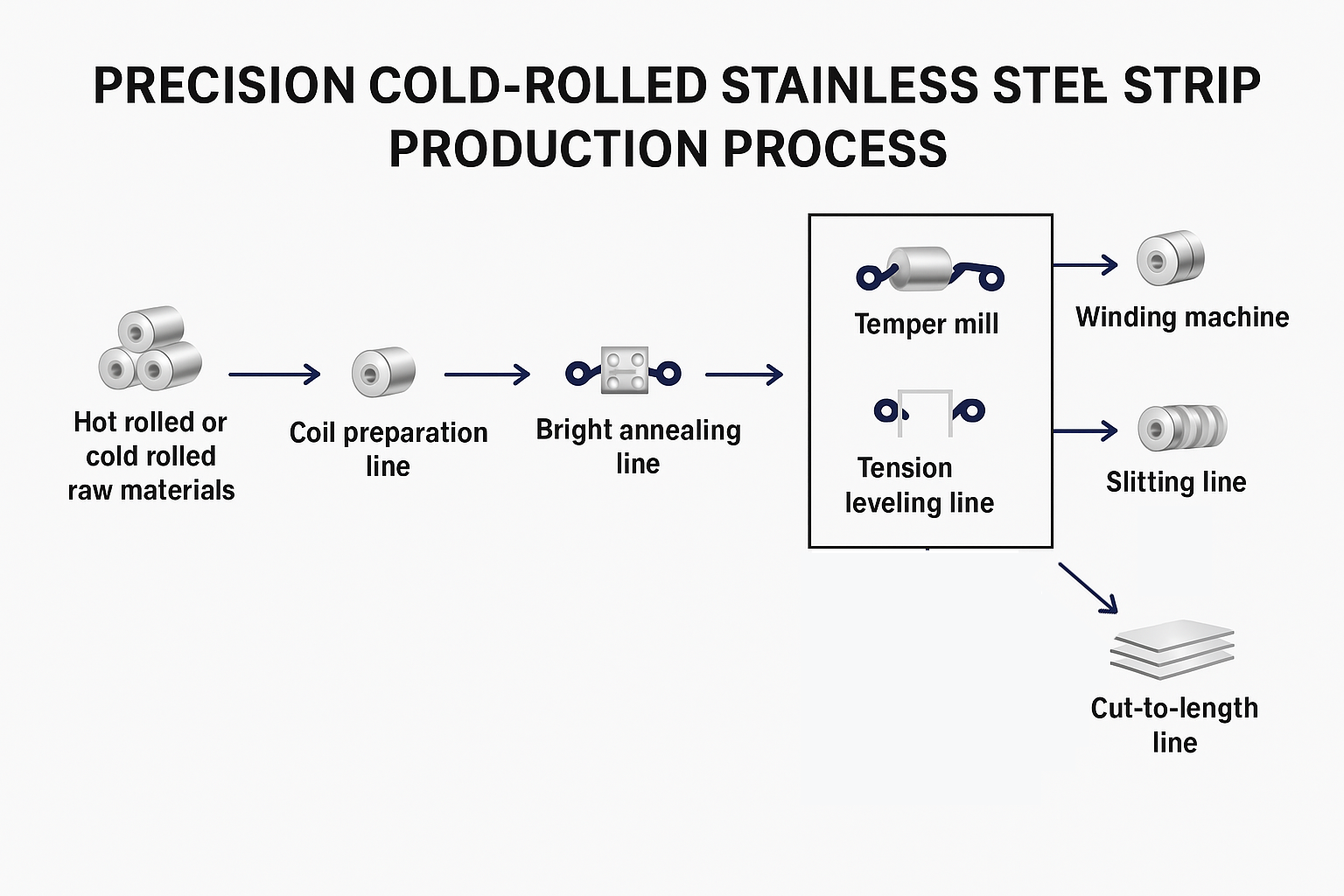

Precision Cold-Rolled Stainless Steel Strip Production Process Flow

- In this process flow, hot-rolled or cold-rolled stainless steel feedstock is reduced to the target gauge at ambient temperature using a high-precision, reversible multi-stand cold-rolling mill

- The cold-rolled strip then undergoes bright annealing in an oxygen-free atmosphere to achieve the required surface finish and mechanical properties specified by the customer

- Following annealing, the strip is processed through a leveling or tension-leveling operation to optimize both surface quality and strip flatness, correcting shape irregularities such as camber and waviness

- This leveling step also relieves residual stresses and further refines the strip’s mechanical characteristics to meet precision cold-rolled stainless steel specifications

- The final product—soft-tempered precision cold-rolled stainless steel strip—exhibits the mechanical properties and surface quality required for downstream forming and fabrication processes