描述

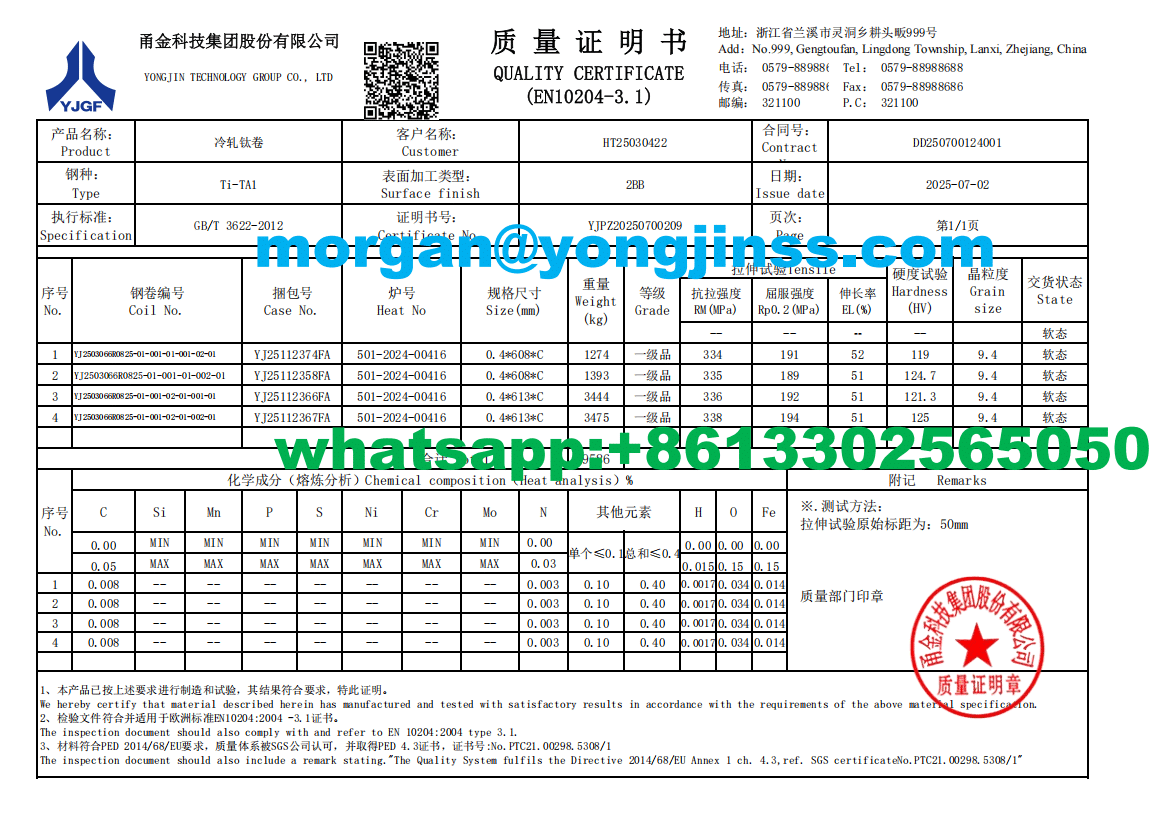

The TA1 series meet diverse industry requirements, widely used in chemical equipment, aerospace components, medical devices and other high-end applications. They exemplify our goal of “controllable quality and cost” in customized titanium production.

Special Versions available:

TA1 (Standard Grade CP Titanium): A common grade with moderate strength, excellent corrosion resistance and formability.

TA1-TM: CP-Ti for general welding and low-elongation forming applications.

TA1-STP: Titanium optimized for stretching and deep drawing processes.

TA1-BS (Black): Black-finished (surface oxidized) designed for standard welding and low-elongation uses.

TA1-DD: For deep drawing with controlled surface finish, ideal for deep/complex stamping.

TA1-BD (Black): Black-finished for deep and multiple drawing operations, suitable for rigorous deep-drawing forming.

YJGF Titanium plant operates a fully integrated production line from sponge titanium through melting, forging and rolling to finished products. Key equipment includes a 10,000‑ton electrode press, multiple 20t/6t VAR furnaces, 7t EB furnaces, and 5,000t/2,000t fast forging presses. With an annual capacity of 60,000 tons, the company demonstrates strong technical strength in titanium processing.

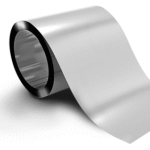

The company’s product range covers the full titanium spectrum: sponge titanium, ingots, plates (coils/thick plates), bars, tubes, wires and various fabricated parts. In particular, our titanium bars come in diverse shapes – round, square, hexagonal – with diameters from 3.0 to 500 mm. Our products serve a wide range of industries including chemical processing, petrochemicals, aerospace, electronics, and biomedical sectors.

More options we can offer