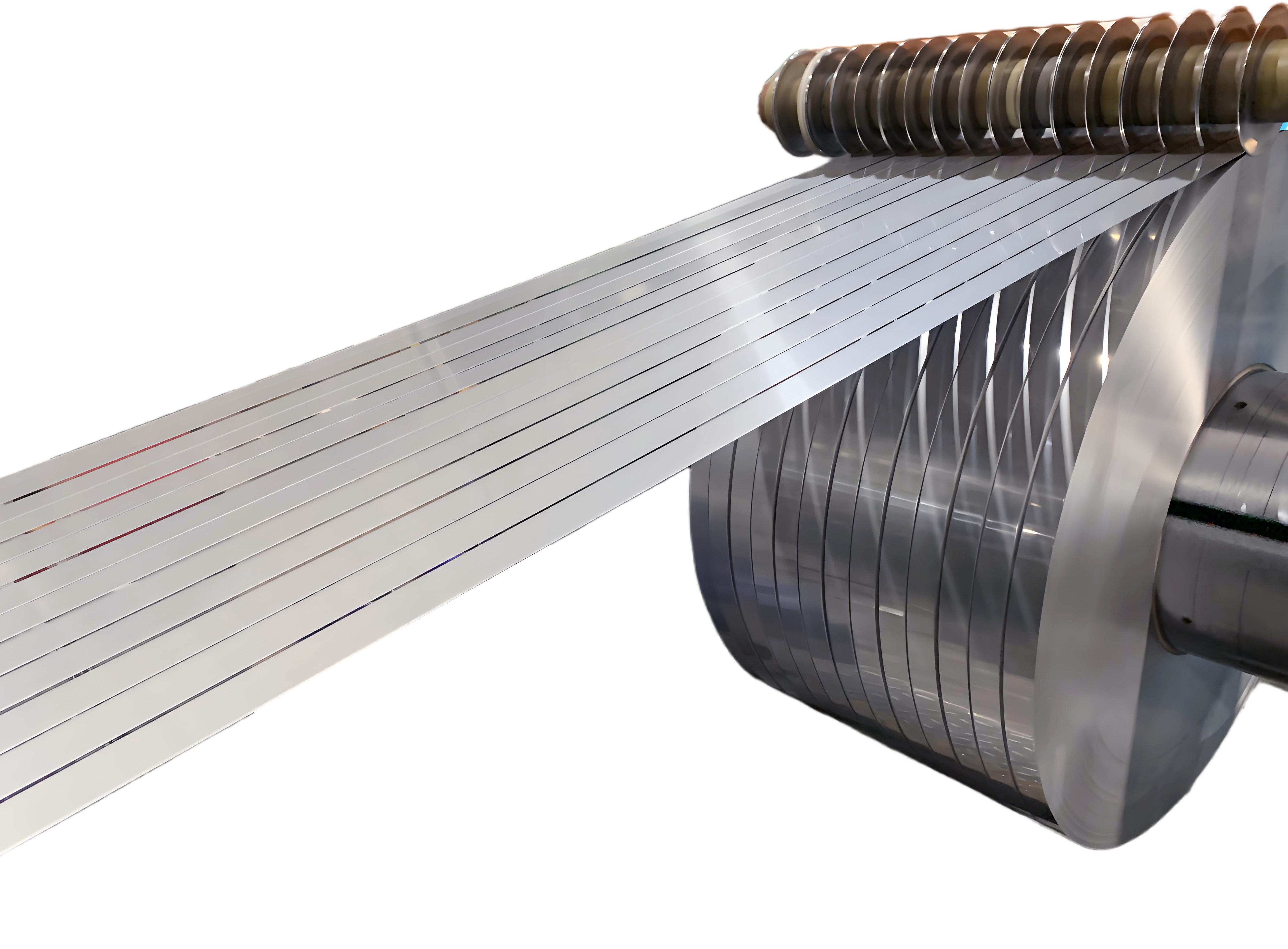

High Precision Slitting Line [1600-Slitting Line]

Technical specifications for stainless steel slitting line:

- Single-pass slitting capacity: Up to 20 strips for materials under 1.0mm thickness

- Film application: Dual-sided protective film application capability

- Multi-strip processing: Partial film application with paper interleaving option

- Coiling specifications:

- Core diameter: 508mm (standard)

- Below 0.6mm thickness: Paper core mandrel required

Key features:

- Combined film/paper protection during slitting operations

- Precision tension control for thin-gauge materials

Key Features

- Dual-sided protective film application capability

- Combined film/paper protection during slitting operations

- Precision tension control for thin-gauge materials

- Width Tolerance:±0.05 mm

Detailed Technical Specifications:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.2–2.5 mm |

| Material Width Range | 800–1540 mm |

| Maximum Coil Weight | 20 tonnes |

| Processing Speed | 60–150 m/min |

| Finished Strip Width Range | 60–1530 mm |

| Maximum Coil OD | 1600 mm (outer diameter) |

| Width Tolerance | ±0.05 mm |

| Single-Shift Capacity | 120 tonnes |

| Manpower per Shift | 3 operators |

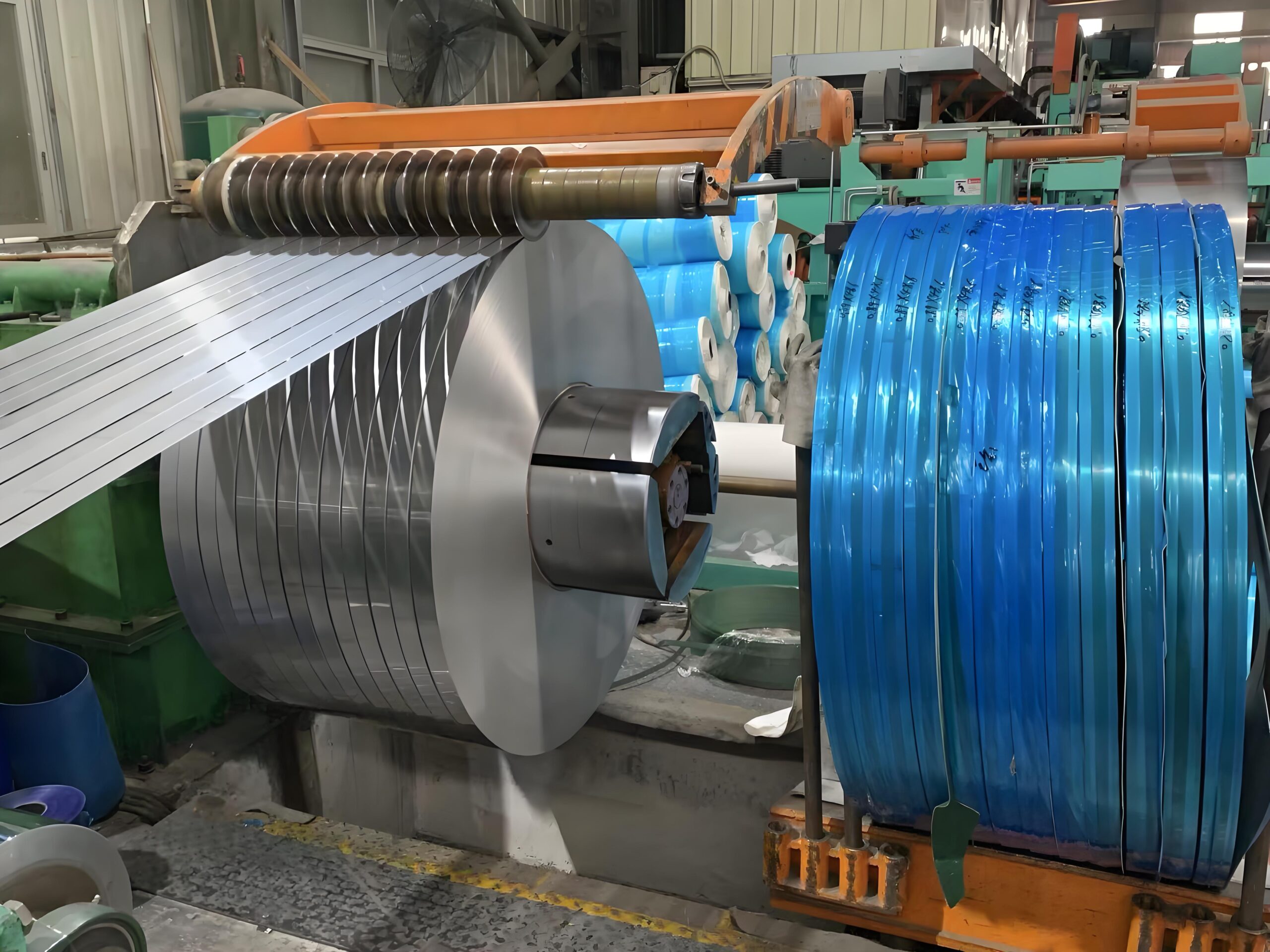

High Precision Slitting Line [850-Slitting Line]

Technical specifications for stainless steel slitting line:

- Single-pass slitting capacity: Up to 20 strips for materials under 0.9mm thickness

- Film application: Single sided protective film application capability

- Paper interleaving:Available

Detailed Technical Specifications:

| Parameter | Specification |

|---|---|

| Material thickness range | 0.1–1.5 mm |

| Material width range | 50–850 mm |

| Maximum coil weight | 7 tonnes |

| Processing speed | 60–120 m/min |

| Finished strip width range | 9–800 mm |

| Maximum coil OD | 1300 mm |

| Width tolerance | ±0.03 mm |

| Single-shift capacity | 50 tonnes |

| Manpower per shift | 2 operators |

Foshan Yongjin New Materials Co., Ltd. is a subsidiary and designated export arm of Yongjin Technology Group (listed: 603995.SH), a global leader in precision stainless steel manufacturing. As an integral part of the Group, we leverage its R&D resources, production expertise, and quality management systems while specializing in delivering tailored material solutions to international markets.

Our quality assurance protocol combines three-tier verification:

ISO 9001-certified production: Advanced inline monitoring systems for thickness tolerance (±0.01mm) and surface roughness

Mill lab Testing: Independent testing mechanical properties (e.g., tensile strength, elongation) and corrosion resistance (ASTM A923/A480).

Pre-shipment inspection: Customizable cargo checks (dimensions, packaging, labeling) with digital documentation for traceability.

Standard orders: 20–35 days (FOB/CIF) with real-time production tracking via our ERP system.

Urgent orders: 12–15 days achievable for repeat clients through reserved capacity slots.

We specialize in high-performance stainless steel composites and precision cold-rolled products, including:

Core Products:

Ultra-thin stainless steel foil (0.05–0.3mm) for flexible electronics and medical devices

Laminated composites (stainless steel + aluminum/copper) for EV battery trays and solar panel frames

Customization:

Tailored widths (200–1,530mm) and surface finishes (2B, BA, No.4, HL)

OEM/ODM solutions for niche applications (e.g., hydrogen fuel cell bipolar plates)

Absolutely. Our products comply with:

Regional Standards: EN 10088 (EU), ASTM A240/A666 (US), JIS G4304 (Asia-Pacific)

Sustainability: REACH/RoHS-compliant, carbon footprint reporting per ISO 14064