Pre-Coated Nickel Breakthroughs: Pusai’s 225,000-Ton Capacity for Global Energy Transition

Established in November 2022, the company leverages Yongjin Group’s decades of expertise in precision cold-rolled stainless steel strip manufacturing to pioneer high-performance battery shell materials for next-generation energy storage solutions

Core Competencies and Technological Advantages

- Legacy of Precision Cold-Rolling Expertise

Building on Yongjin Group’s leadership in cold-rolled stainless steel production, Pusai integrates advanced metallurgical technologies and proprietary processes. Its parent company operates multiple cold-rolling facilities across China, including mature production bases in South and East China, ensuring robust technical support for high-precision material development

- Strategic R&D Collaboration

Pusai collaborates with leading universities and research institutions to refine pre-coated nickel (pre-plated nickel) technology, a critical innovation for enhancing battery performance. This collaborative model accelerates breakthroughs in material science and process optimization

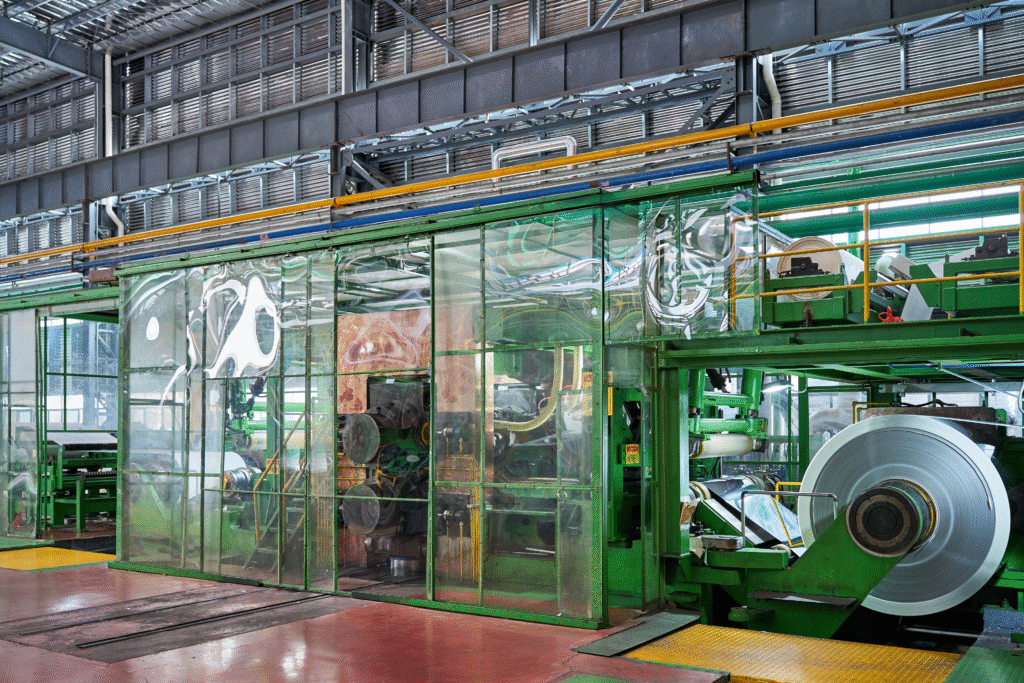

- Large-Scale Production Capability

- With a total investment of ¥1.4 billion, Pusai is constructing a 225,000-ton annual production line for cylindrical battery shell materials. The project is divided into two phases:

- Phase I: A 75,000-ton production line for 4680 battery shells, operational by 202418.

- Phase II: A 150,000-ton expansion targeting 3C electronics, power batteries, and energy storage components

Product Highlights: Pre-Coated Nickel Battery Shell Materials

Pusai’s flagship product, pre-coated nickel stainless steel strips, is engineered for high-end lithium-ion batteries, particularly Tesla’s 4680 cylindrical cells. Key advantages include:

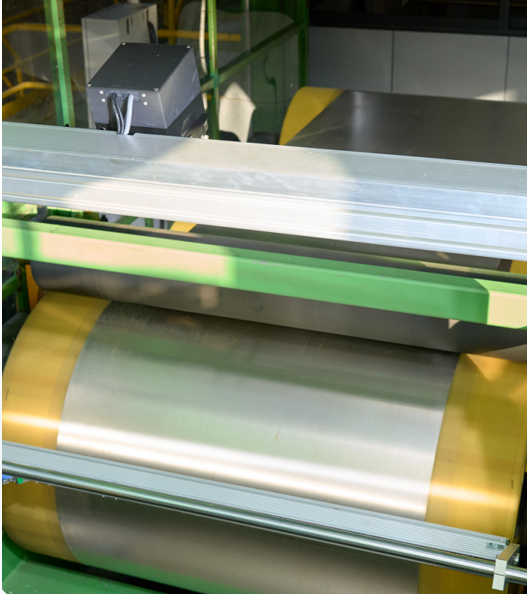

- Superior Consistency and Durability

- Pre-coated nickel technology applies a uniform nickel layer to stainless steel strips before stamping, eliminating post-plating defects like scratches or nickel powder shedding. This ensures higher corrosion resistance, airtightness, and voltage stability, critical for battery longevity and safety126.

- Compared to traditional post-plated nickel shells, Pusai’s solution reduces risks of micro-short circuits, enhancing overall battery reliability

- Optimized for Next-Gen Batteries

- The 4680 battery, with 4x the capacity of its predecessor (2170 cells), demands ultra-precise shell materials. Pusai’s products meet stringent dimensional tolerances (e.g., thickness: 0.25–0.30 mm, width: ≤1,200 mm) as per GB/T34212-2017 standards36.

- The material’s excellent stamping performance supports efficient mass production, aligning with Tesla’s vision of reducing cell counts per vehicle (e.g., 950 cells for 4680 vs. 7,100 for 18650)

- Sustainability-Driven Innovation

- By replacing imported materials and reducing reliance on energy-intensive post-plating processes, Pusai contributes to greener manufacturing practices in the EV sector

Market Positioning and Growth Potential

- Global Demand Surge: The pre-coated nickel market is projected to grow from 200,000 tons (2021) to 600,000–700,000 tons by 2025, driven by EV adoption and energy storage needs

- Domestic Leadership: Pusai competes with international giants like Japan’s Toyo Kohan and Nippon Steel, positioning China as a key player in this high-value niche